Call Us: 08045477254

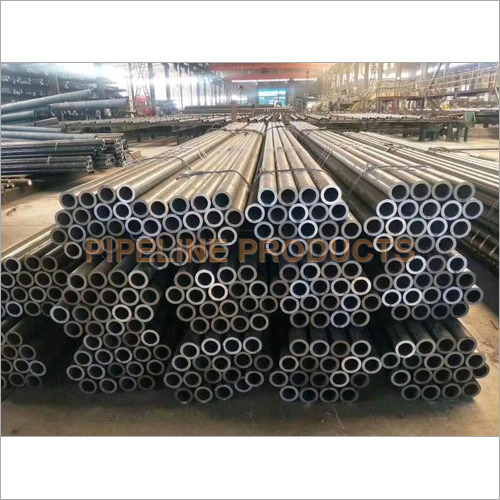

CS Seamless Pipe

58 INR/Kilograms

Product Details:

- Section Shape Round

- Surface Finish Black Painted / Mill Finish

- Material Carbon Steel

- End Protector Plastic Caps

- Connection Welded or Threaded

- Feature High Strength, Corrosion Resistant, Durable

- Tolerance 0.03 mm

- Click to View more

X

CS Seamless Pipe Price And Quantity

- 500 Kilograms

- 58 INR/Kilograms

CS Seamless Pipe Product Specifications

- Seamless

- Round

- Black Painted / Mill Finish

- 0.03 mm

- ASTM A106, ASTM A53, API 5L, DIN, JIS

- Carbon Steel

- 1/2 to 24 (21.3 mm to 609 mm)

- Seamless

- 2 mm to 40 mm

- Varies as per Requirement

- Plastic Caps

- A, B, C, GR.B, ST52, API 5L GR.B, X42, X52

- Non-Alloy

- 5.8m, 6m, 11.8m, 12m or as required

- High Strength, Corrosion Resistant, Durable

- Welded or Threaded

- Oil and Gas, Structural, Mechanical, Boiler, High-Pressure Applications

- Pipe

- Round

- Oiled, Black Painted, Galvanized

CS Seamless Pipe Trade Information

- 5000 Kilograms Per Week

- 2-5 Days

Product Description

Specification

- Dimensions : ASTM, ASME and API

- Standard : ASTM A554, A312, A778, JIS G3446, CNS G3119, GB

- Material Grade 304, 304L/H, 304LN, 309H, 310/S/H, 316, 316L/H, 316TI, 317, 317L, 321/H, 347/H 410, 446, 904L

- Size : 1/8 NB to 24 NB, 1/4 OD to 24 OD

- Length :Up to 6 meters, custom cut lengths

- Thickness :1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

- Type :As Welded, EFW, ERW, Seamless, Semi Seamless, Bead Removed

- Surface : Inside Electropolished , Outside Mirror Finish

- Application : Dairy Produce, Brewery, Food, Pharmacy, Beverage, Cosmetics, Chemical Industry

Multi-Layered Inspection & Quality Testing

Each CS seamless pipe undergoes thorough hydrostatic, eddy current, and ultrasonic testing to guarantee structural integrity and performance. These stringent inspection processes ensure the pipes can withstand high-pressure environments and demanding applications, providing peace of mind for critical projects.

Custom Sizes, Superior Strength, Wide Applications

With a variety of sizes and thicknesses available, our seamless pipes are well-suited for oil and gas, mechanical, boiler, and other high-pressure applications. Their excellent strength, dimensional accuracy, and durable surface finishes make them a reliable choice for diverse industries.

Flexible Delivery and Export Packaging

To suit global requirements, we offer standard export packaging or custom packaging upon request. Pipes are dispatched from any Indian port, ensuring convenient and timely delivery worldwide. Minimum order quantity is just 1 ton, making us adaptable to your projects scale and demands.

FAQs of CS Seamless Pipe:

Q: How are CS seamless pipes tested for quality and reliability?

A: CS seamless pipes are extensively tested using hydrostatic, eddy current, and ultrasonic inspections. These methods evaluate the pipes strength, detect internal or surface defects, and verify the pipes integrity to meet industry standards.Q: What are the primary applications of these seamless pipes?

A: These seamless pipes are widely used in oil and gas transmission, structural implementations, mechanical systems, boilers, and high-pressure environments due to their durability and high strength.Q: When can delivery be expected after placing an order?

A: Delivery timelines depend on the order size and customization, but we ensure prompt dispatch from any Indian port. Standard lead times are communicated upon order confirmation.Q: Where are these pipes manufactured and dispatched from?

A: Our CS seamless pipes are manufactured in India and can be dispatched from any major Indian port, ensuring flexibility and efficiency for global shipments.Q: What is the process for ordering pipes with custom specifications?

A: You can specify your required diameter, thickness, length, surface treatment, and packaging. Our team accommodates custom and standard requirements, with a minimum order quantity of 1 ton.Q: What are the benefits of choosing CS seamless pipes over other types?

A: Choosing CS seamless pipes offers enhanced mechanical strength, uniformity, corrosion resistance, and precise tolerance, making them suitable for rigorous and high-pressure applications.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free