Call Us: 08045477254

MS Weld Pipe Fittings

Product Details:

- Tensile Strength 410 MPa

- Coating Type Black Paint / Zinc Coated

- Thread Type Not Applicable (Welded Fitting)

- Tolerance 0.5 mm

- Temperature Range -20C to 400C

- Diameter 15 mm to 600 mm

- Yield Strength 250 MPa

- Click to View more

X

MS Weld Pipe Fittings Price And Quantity

MS Weld Pipe Fittings Product Specifications

- ASTM A234 / IS 1239 / IS 3589

- -20C to 400C

- Black Painted / Galvanized

- 2 mm to 12 mm

- Butt Weld

- As per Fitting Design

- Up to 20 Bar

- Industrial, Plumbing, Gas, Water Supply

- Rigid

- 15 mm to 600 mm

- 250 MPa

- Metal to Metal

- Mild Steel (MS)

- Custom / As per requirement

- Round

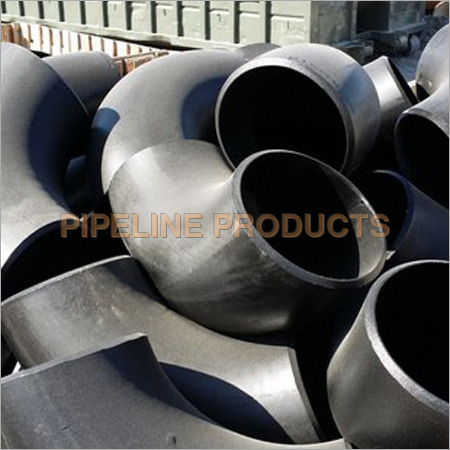

- MS Weld Pipe Fittings

- Not Applicable (Welded Fitting)

- IS 2062 / IS 1239

- Welded

- 410 MPa

- Black Paint / Zinc Coated

- Elbow, Tee, Reducer, Coupling, Cap

- Black

- 15 mm to 600 mm

- 0.5 mm

- Pipe Joining, Fluid Conveyance, Structural Purpose

MS Weld Pipe Fittings Trade Information

- 100 Piece Per Week

- 1 Week

Product Description

Discover our rare MS Weld Pipe Fittings at a reduced price-an exceptional offering for those seeking both reliability and value. Each monumental fitting is hydro tested and undergoes rigorous inspection, ensuring a venerable standard of safety and precision. Crafted using seamless, ERW, or fabricated forms with a robust hot-rolled or cold-formed manufacturing process, these bevelled-end fittings boast superior corrosion resistance with advanced coating. Ideal for demanding industrial and structural projects, they are available in a range of shapes and sizes, all finished with meticulous black painting or galvanization. Now marked down for a limited period!

Versatile Applications Across Industry Sectors

MS Weld Pipe Fittings are engineered for versatile performance in fluid conveyance, pipe joining, and structural applications. Valiant and robust, they cater to general and specific uses in industries such as gas distribution, water supply, and plumbing systems. With their dependable corrosion resistance and long service life, these fittings are ideally suited for use in both light-duty and heavy-duty operations where reliability is paramount.

Packaging, Supply, and Sampling Details

Every order of MS Weld Pipe Fittings is carefully packaged in either gunny bags or wooden boxes to ensure secure delivery. Supply ability is attuned to your project requirements, with a dynamic outlay to match varying order sizes. Samples are available upon request, allowing you to evaluate our quality before committing to a full asking price-ensuring a seamless procurement experience.

Versatile Applications Across Industry Sectors

MS Weld Pipe Fittings are engineered for versatile performance in fluid conveyance, pipe joining, and structural applications. Valiant and robust, they cater to general and specific uses in industries such as gas distribution, water supply, and plumbing systems. With their dependable corrosion resistance and long service life, these fittings are ideally suited for use in both light-duty and heavy-duty operations where reliability is paramount.

Packaging, Supply, and Sampling Details

Every order of MS Weld Pipe Fittings is carefully packaged in either gunny bags or wooden boxes to ensure secure delivery. Supply ability is attuned to your project requirements, with a dynamic outlay to match varying order sizes. Samples are available upon request, allowing you to evaluate our quality before committing to a full asking price-ensuring a seamless procurement experience.

FAQ's of MS Weld Pipe Fittings:

Q: How are MS Weld Pipe Fittings commonly used in industrial projects?

A: MS Weld Pipe Fittings are commonly used to join pipes and convey fluids in industrial, plumbing, gas, and water supply lines. Their high strength and corrosion resistance make them ideal for structural and fluid delivery applications.Q: What is the manufacturing process for these pipe fittings?

A: They are manufactured using hot rolled or cold formed processes, ensuring precise tolerances and consistent quality across seamless, ERW, and fabricated forms.Q: Where can these fittings be installed?

A: These fittings are suitable for installation in a variety of environments such as industrial plants, commercial buildings, and infrastructure projects requiring robust pipe joining solutions.Q: What coating options are available for corrosion resistance?

A: The fittings are available with black paint or zinc coating, greatly enhancing their ability to withstand corrosion in challenging environments.Q: When can I expect delivery and is sample evaluation possible before purchase?

A: Delivery timelines depend on order quantity and requirements, and samples are available upon request to help you evaluate quality before making a larger purchase.Q: How do I ensure correct installation of these fittings?

A: Proper installation involves welding the bevelled ends as per industry standards and verifying fitment through visual and dimensional inspection. Detailed guides can be provided upon request.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free