Call Us: 08045477254

Welding Fittings

Product Details:

- Sealing Type Metal-to-Metal

- Temperature Range -30C to 450C

- Coating Type None / Custom on Request

- Flexibility Rigid

- Thread Type N/A (Welded Connection)

- Yield Strength 205 MPa Minimum

- Tolerance 0.01 mm

- Click to View more

X

Welding Fittings Price And Quantity

Welding Fittings Product Specifications

- 205 MPa Minimum

- Elbow, Tee, Reducer, Cap, Coupling (as per requirement)

- Polished / Pickled / Sand Blasted

- Welded

- Oil & Gas, Petrochemical, Power Plant, Water Treatment

- Welding Fittings

- Metallic Silver

- 0.01 mm

- Up to 6000 PSI

- 12 mm to 600 mm

- 1D, 1.5D, 2D, Custom

- 520 MPa Minimum

- 1/2 to 24 (DN15 to DN600)

- Butt Weld

- Metal-to-Metal

- ANSI B16.9 / ASTM A403 / DIN / JIS / EN

- -30C to 450C

- None / Custom on Request

- Rigid

- 304, 304L, 316, 316L, 321, 347, etc.

- Standard / Custom as per order

- Round

- Schedule 10, 20, 40, 80 (as specified)

- Stainless Steel

- Pipe Fitting, Industrial Piping Systems

- N/A (Welded Connection)

Welding Fittings Trade Information

- 100 Piece Per Week

- 1 Week

Product Description

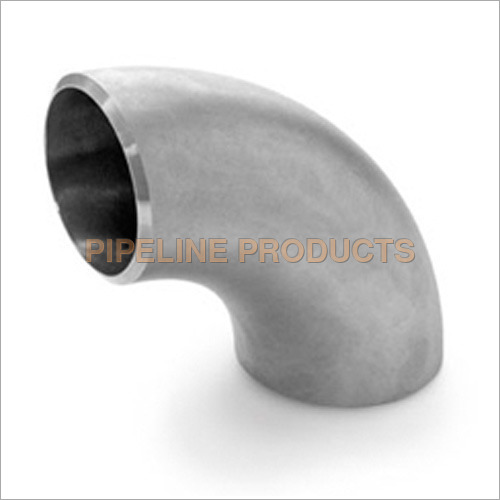

Discover our sought-after welding fittings, a champion choice for outstanding pipe joint reliability. Ephemeral in their installation yet enduring in performance, these stainless steel fittings boast excellent corrosion resistance and are manufactured through cold or hot forming. Designed with beveled ends per ASME B16.25, each fitting undergoes hydrostatic, NDT, and PMI testing. The instant checkout process ensures quick lead times of 2-4 weeks. Highly recommended for critical applications, these fittings are meticulously packaged and available in elbows, tees, reducers, and more, and compliant with major global standards.

Versatile Uses and Exceptional Features of Welding Fittings

Welding fittings are integral to diverse sectors including oil & gas, petrochemical, power plants, and water treatment. These fittings excel in commercial and industrial piping systems, handling pressures up to 6000 PSI and temperatures from -30C to 450C. Precision tolerance of 0.01 mm, multiple surface treatments, and customizable options add to their appeal. With outstanding corrosion resistance, these round-section, metallic silver fittings ensure safe, durable, and rigid connections, elevating reliability for demanding projects.

Certifications, Export Destinations, and Payment Flexibility

Our welding fittings comply with ANSI B16.9, ASTM A403, DIN, JIS, and EN standards, championing consistent quality and safety. These outstanding products are exported worldwide, with principal markets in Europe, Asia, and the Middle East. Customers benefit from express shipping and robust export-grade packing. Outlay is simplified with flexible payment terms, and orders are promptly handed over upon completion. Our export experience guarantees swift delivery and satisfaction for every order.

Versatile Uses and Exceptional Features of Welding Fittings

Welding fittings are integral to diverse sectors including oil & gas, petrochemical, power plants, and water treatment. These fittings excel in commercial and industrial piping systems, handling pressures up to 6000 PSI and temperatures from -30C to 450C. Precision tolerance of 0.01 mm, multiple surface treatments, and customizable options add to their appeal. With outstanding corrosion resistance, these round-section, metallic silver fittings ensure safe, durable, and rigid connections, elevating reliability for demanding projects.

Certifications, Export Destinations, and Payment Flexibility

Our welding fittings comply with ANSI B16.9, ASTM A403, DIN, JIS, and EN standards, championing consistent quality and safety. These outstanding products are exported worldwide, with principal markets in Europe, Asia, and the Middle East. Customers benefit from express shipping and robust export-grade packing. Outlay is simplified with flexible payment terms, and orders are promptly handed over upon completion. Our export experience guarantees swift delivery and satisfaction for every order.

FAQ's of Welding Fittings:

Q: How are the welding fittings tested for quality and durability?

A: Each welding fitting undergoes thorough hydrostatic testing, non-destructive testing (NDT), and positive material identification (PMI) to guarantee structural integrity, corrosion resistance, and consistent material quality.Q: What manufacturing processes are used for these fittings?

A: Our welding fittings are produced using cold formed or hot formed processes, meeting global standards such as ANSI B16.9, ASTM A403, and others to ensure outstanding fitment and mechanical properties.Q: When can I expect my order to be delivered after purchase?

A: Lead times for standard or custom fittings range from 2 to 4 weeks depending on order quantity. Express shipping options are available for urgent requirements, ensuring timely project delivery.Q: Where are these welding fittings primarily used?

A: These fittings are highly recommended for installation in oil & gas plants, petrochemical industries, power generation facilities, water treatment systems, and other robust industrial applications.Q: What are the benefits of choosing your stainless steel welding fittings?

A: Our fittings provide excellent corrosion resistance, dependable metal-to-metal sealing, rigid construction, and a wide temperature/pressure range, making them a champion solution for demanding environments.Q: How are the fittings packaged for export?

A: To preserve quality during transit, fittings are securely packed with plastic caps, placed in wooden cases, and export packing is applied to ensure safe delivery.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese